Redmoor Project

The Redmoor Project Overview:

Developing a World-Class Tungsten - Tin - Copper Resource

Overview

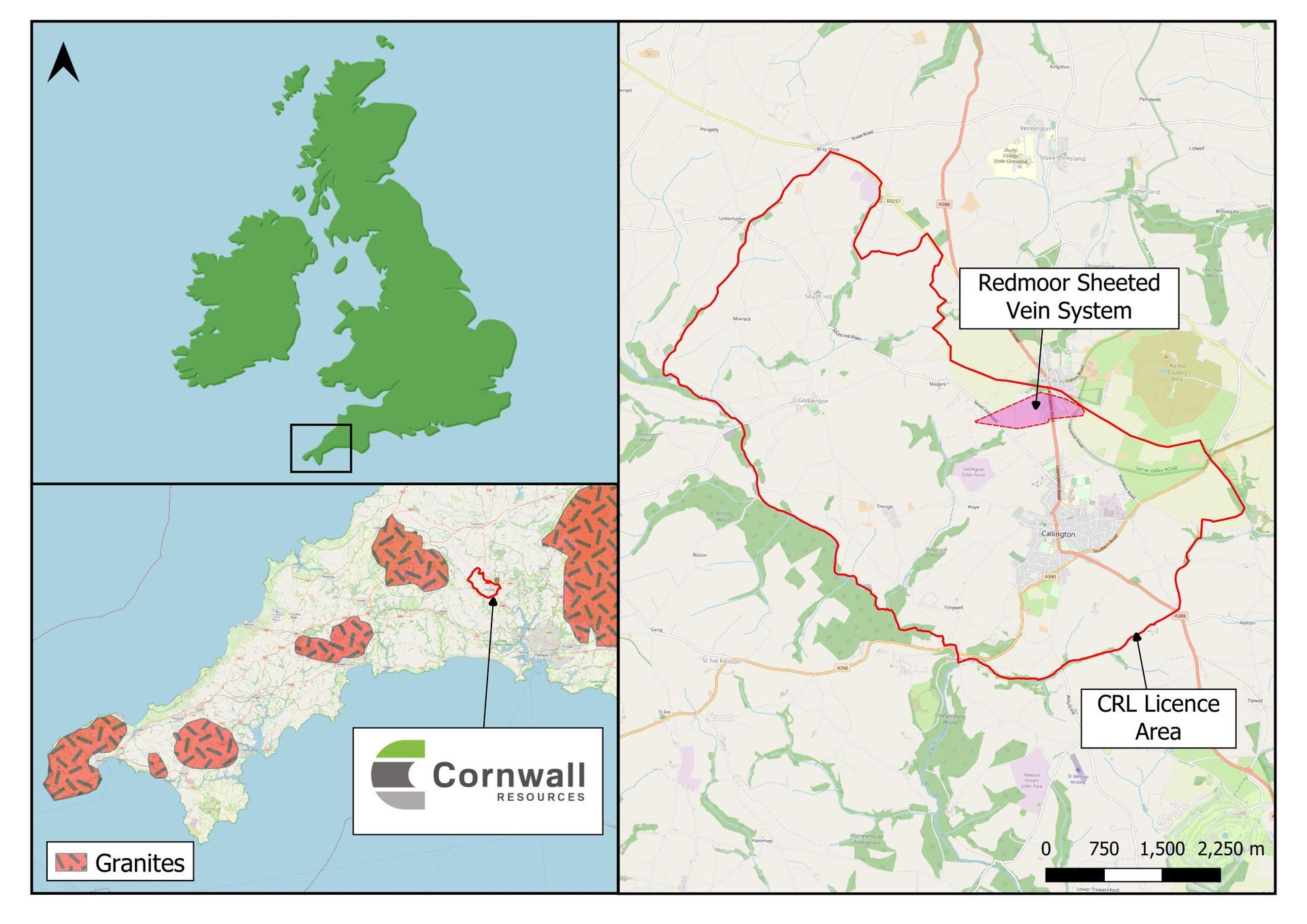

The Redmoor Project is located between the village of Kelly Bray and the town of Callington in southeast Cornwall, approximately 25 km by road from the city and port of Plymouth. The area has well-established infrastructure and is located in the historically significant Cornish mining district.

Cornwall Resources Limited ("CRL") control the mineral rights within a 23km² licence area, within which the Redmoor Sheeted Vein System ("SVS") is located. Through exploration drilling and related activities, CRL have developed an inferred Mineral Resource Estimate of 11.7 Mt @ 1.17% Sn equivalent composed of high-grade zones of Tungsten - Tin - Copper mineralisation within the SVS.

History

The original Redmoor Mine is one of a group of mines (Redmoor, Holmbush and Kelly Bray) that were opened in the 18th century and continued operating until 1892 when they were forced to close due to low tin prices. Sections of the Redmoor Mine were re-opened between 1907 and 1914 and again in 1934. Historical records show operations at the Redmoor Mine, Kelly Bray Mine, and Wheal Florence Mine. Historic production amounted to 574 t tin, 268 t tungsten trioxide, 852 t Copper, 153 t lead and 9,179 oz silver.

Slide title

Redmoor mine, 1945

Button

Slide title

Callington United Mines historic share certificate

Button

Slide title

Prince of Wales visits Callington tungsten mine, 1918

Button

Project Ownership

CRL has an agreement with the mineral rights holder of the Redmoor area, providing the right to explore the area until 2037, and the further right for CRL to enter into a 25-year mining lease (renewable for a further 25 years). The mining lease permits commercial extraction of the minerals, subject to obtaining planning and other approvals.

Geology

The geology of the Redmoor Project is typical of other established mining areas of Cornwall. Tungsten, tin and sulphide mineralisation is spatially related to granite intrusions, which caused mineralising fluids to be mobilised along fractures and faults in host rocks. Redmoor is located adjacent to the Kit Hill granite intrusion, which is the focus of a number of historic mines, both within and contiguous to the east of CRL’s mineral rights.

At Redmoor, tungsten and tin-oxide, and other base metal sulphide mineralisation occur both in discrete veins or lodes (e.g. Johnson’s Lode, Kelly Bray Lode) and within a zone of numerous closely-spaced sub-parallel narrow mineralised quartz-veins known as the Sheeted Vein System (“SVS”). The SVS contains high-grade zones where there is a higher density of mineralised quartz veins. These high grade zones within the SVS form the basis of the Inferred Mineral Resource.

Tungsten and copper mineralised drill core from Redmoor drilling

Previous Exploration, Testwork and Studies

The Redmoor area has seen considerable previous exploration. Between 1979 and 1985, exploration company South West Minerals Limited completed a 35 hole diamond drilling programme (totalling 12,146 m), assisted by a government led Minerals Assistance Program. These holes intersected significant mineralisation adjacent to the old workings.

Metallurgical test work was carried out on crushed diamond drill core. The results of this testwork were used for flowsheet and engineering design of a planned processing plant. A mine design was produced along with feasibility studies aimed at constructing a mine and processing plant at Redmoor. However, as a result of the tin price crash in the 1980s arising from the collapse of the International Tin Council, the project did not proceed.

In 2015, a detailed review of previous metallurgical testwork was carried out, through consultant, Devlure. This concluded that the Redmoor ore is coarse grained, a simple, low-cost ore to process and that overall process recoveries of 68% tin, 72% tungsten, and 35% – 85% copper (depending on flowsheet design) might be expected.

CRL Exploration and Resource Estimate

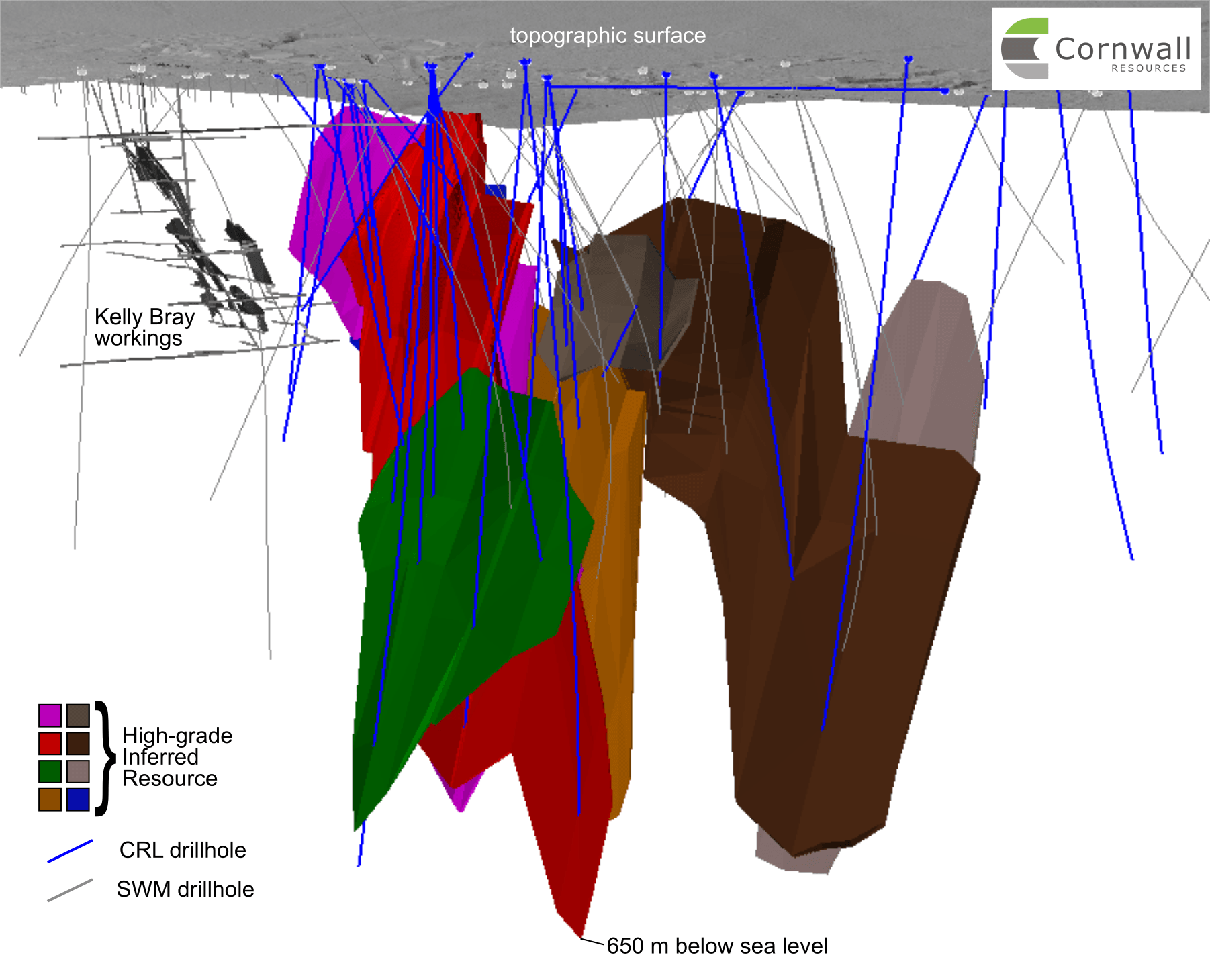

In January 2017 CRL hired a team of experienced geologists who carried out an initial data review. Following this, in March 2017, CRL commenced a drill program of 20 diamond holes for 7,046 m in total. This program was successful in identifying high-grade zones within the SVS, which formed the basis of the 2018 high-grade Inferred Resource, of 4.5 mt @ 0.37% WO3, 0.25% Sn, and 0.57% Cu, issued by SRK (UK).

As a result of the success of this program, a further drill program was carried out by CRL in 2018, aimed at targeting deeper ‘Target’ potential. 12 holes were drilled for 7,370 m. All boreholes intersected mineralisation, thus confirming the 2018 resource model. An updated Inferred mineral resource dated 14 February 2019 was produced by Cornwall based consultants Geologica (UK) and totals 11.7 mt @ 0.56% WO3, 0.16% Sn, and 0.50% Cu, at a cut-off grade of 0.45% (SnEq). The geological model for this is shown below.

Technical Studies

A Cornwall-based consulting metallurgist, experienced in processing Cornish ores, has been retained by CRL to review and guide metallurgical testwork. A process plant engineering and surface infrastructure study was completed by British company Fairport Engineering in April 2018, and further updated in 2019. Fairport have recent experience with the design and build of tungsten processing plants in Europe. This study included capital and operating cost estimates for a potential processing plant and mine surface infrastructure.

Following this, a scoping level mining study was completed by Cornwall-based consultants Wardell Armstrong (WAI) in September 2020. This considered geotechnical and social factors to establish an indicative potential mine design. Mining would be via decline access with long-hole stoping and with paste fill. The mine schedule has been optimised to ensure access to high grade material in the early years of the project. The mine plan is based on an indicative production rate at 600k tonnes per annum (tpa), with a potential mine life of 12 years based on 7.2 million tonnes of feed over the life of mine.

As part of this work, WAI produced an independent economic assessment, which utilised costs derived from the Fairport work together with the updated mine schedule. This shows that the Redmoor Project is potentially economically attractive.